📘 قراءة كتاب REQUIREMENTS OF GOOD MANUFACTURING PRACTICE أونلاين

REQUIREMENTS OF GOOD MANUFACTURING PRACTICE من كتب علمية

REQUIREMENTS OF GOOD MANUFACTURING PRACTICE

REQUIREMENTS OF GOOD MANUFACTURING PRACTICE من كتب علميةREQUIREMENTS OF GOOD MANUFACTURING PRACTICE

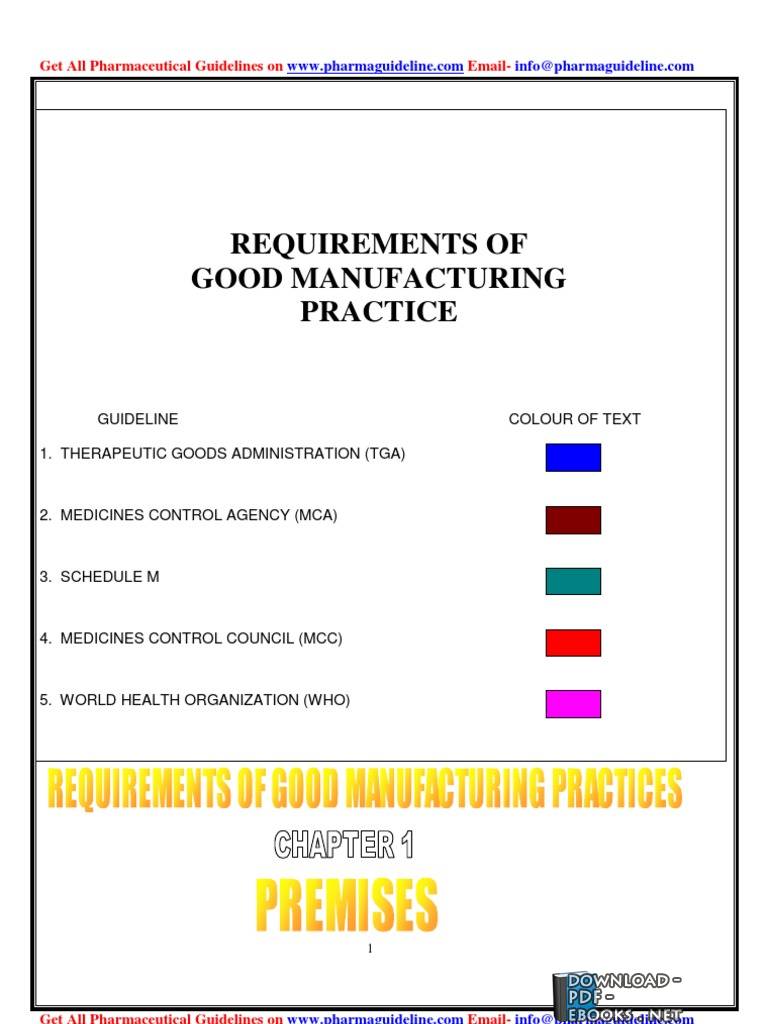

REQUIREMENTS OF

GOOD MANUFACTURING

PRACTICE

GUIDELINE COLOUR OF TEXT

1. THERAPEUTIC GOODS ADMINISTRATION (TGA)

2. MEDICINES CONTROL AGENCY (MCA)

3. SCHEDULE M

4. MEDICINES CONTROL COUNCIL (MCC)

5. WORLD HEALTH ORGANIZATION (WHO)

NOTE : (The number mentioned against each point is clause no. as per respective guidelines)

1. BUILDINGS AND GROUNDS

TGA:

a. General

101. Buildings should be located, designed, constructed, adapted and maintained to suit the operations

carried out in them.

Except where special precautions are taken to isolate an interior manufacturing space, buildings

should be sited away from incompatible activities such as those that generate chemical or biological

emissions.

102. Buildings, including receiving and despatch areas, should be designed, constructed and maintained

so as to protect against the effects of weather or ground seepage and the entry and harboring of

vermin, birds, pests and pets. Cavities and voids should not be present unless sealed or provided with

access for pest control.

103. Animal houses should be isolated from production areas, with separate entrances and air handling

facilities, and should comply with the current edition of the NH& MRC/CSIRO/AAC Code of

practise for the care and use of animals for experimental purposes.

104. Grounds should be established and maintained so as to minimize ingress into the buildings of dust,

soil or other contaminants and should be maintained in an orderly condition.

b. Pipes, ducts and service area

105. Pipelines carrying services or products between rooms or areas should be identified by colour or by

standard markings at suitable intervals and the direction of flow shown.

Particular care should be taken that product pipelines are not inter-connected or connectable in a

manner that invites cross-contamination or product mix-up.

“Dead legs” (in which circulation cannot occur) should be minimized.

106. In production areas –

* Extraction ducts should be designed to be cleanable and to prevent condensate or accumulated dust

from falling back into product or equipment.

* There should be no recesses that cannot be cleaned and a minimum of projecting ledges, shelves,

cupboards, pipes, fixtures and fittings

* Exposed overhead roof joists, pipes and ducts should be avoided. Where they are unavoidable,

special cleaning procedures and schedules should be written and followed.

* Exposed pipes should not touch walls, but be suspended from or supported by brackets, sufficiently

separated to allow thorough cleaning.

* Opening in walls, floors or ceilings through which piping, ducting or other non-structural items

pass should be sealed or have removable covers that permit cleaning.

* Light fittings should be located and/or sealed so as not to collect and deposit contamination.

107. Production areas should not normally contain service machinery, or its associated ductwork or

pipe-work, except where the ducting or pipes connect directly to equipment. Rooms or areas

CE

gmp pharmaceutical industry

gmp ppt

good manufacturing practice pdf

gmp بالعربي

gmp course

gmp pdf عربي

gmp airport

gmp معنى

حجم الكتاب عند التحميل : 3.1 ميجا بايت .

نوع الكتاب : pdf.

عداد القراءة:

اذا اعجبك الكتاب فضلاً اضغط على أعجبني و يمكنك تحميله من هنا:

شكرًا لمساهمتكم

شكراً لمساهمتكم معنا في الإرتقاء بمستوى المكتبة ، يمكنكم االتبليغ عن اخطاء او سوء اختيار للكتب وتصنيفها ومحتواها ، أو كتاب يُمنع نشره ، او محمي بحقوق طبع ونشر ، فضلاً قم بالتبليغ عن الكتاب المُخالف:

قبل تحميل الكتاب ..

قبل تحميل الكتاب ..

يجب ان يتوفر لديكم برنامج تشغيل وقراءة ملفات pdf

يمكن تحميلة من هنا 'http://get.adobe.com/reader/'

منصّة المكتبة

منصّة المكتبة